Continuous Improvement (CI) has historically been synonymous with the manufacturing sector, sparking notable advancements and operational efficiencies.

However, the realm of CI extends far beyond production lines, permeating various industries such as healthcare, customer service, logistics, construction, retail, financial services and more.

In the contemporary business landscape, leveraging these strategies has become pivotal for sustained success and growth.

Recent insights from Manufacturing Digital indicate that a significant 69.7% of manufacturers integrate diverse lean practices – showing that they do work in any of the settings, but also amplifying that can also be transferable as a skill set, rather than to just a sector as manufacturing is in itself a broad spectrum of industries.

While the application of specific methodologies can pose challenges, the potential rewards they offer cannot be overstated in the competitive business environment.

According to earlier research, the adoption of these types of practices has demonstrated a multitude of benefits, including substantial reductions in inventory, lead time, and rework, as well as notable improvements in delivery targets, productivity, and overall quality.

While some might argue that these statistics are difficult to pinpoint fully, there is no denying the tangible advantages of implementing continuous improvement practices to a site or sector.

Integrating these kinds of practices can enable businesses to:

- Meet customer demands with greater precision and punctuality by eliminating non-value-added processes

- Streamline work-in-progress inventory to achieve a more agile operational framework

- Foster adaptability and responsiveness in the face of evolving market dynamics

- Minimise rework and associated costs to enhance overall process efficiency

- Cultivate a versatile and multi-skilled workforce equipped to respond swiftly to changing demands

This further shows that the need for improvement doesn’t only factor within the manufacturing environment. If you look at any job or sector, there are always ways to improve, be it in time, money, energy and resource.

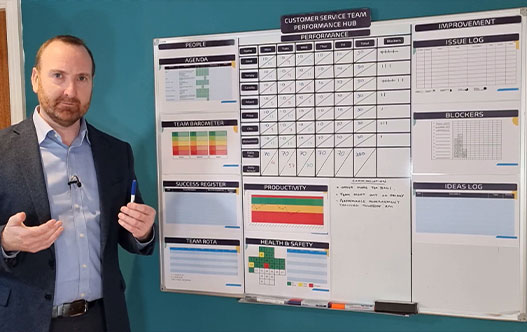

Dan Briscoe, Managing Director of click2 learn, said they had seen businesses across all sectors that embrace Continuous Improvement and Practical Problem Solving (PPS) methods of training could see a productivity and performance improvement of up to 10-30% within the first year.

He also highlighted the significance of integrating these skills comprehensively across the workforce, from the shop floor, to the boardroom table.

Mr Briscoe said: “Harnessing the power of Continuous Improvement and Lean methodologies is not exclusive to top-tier executives or entry-level staff. It’s crucial for every member of the organisation to be well-versed in these principles to drive collective growth and innovation. But what is important is that it is recognised that as a business, this type of training is a way to shape the environment and get everyone speaking in a consistent manner – sharing the same methodology, approach and event language for improvement across the board.

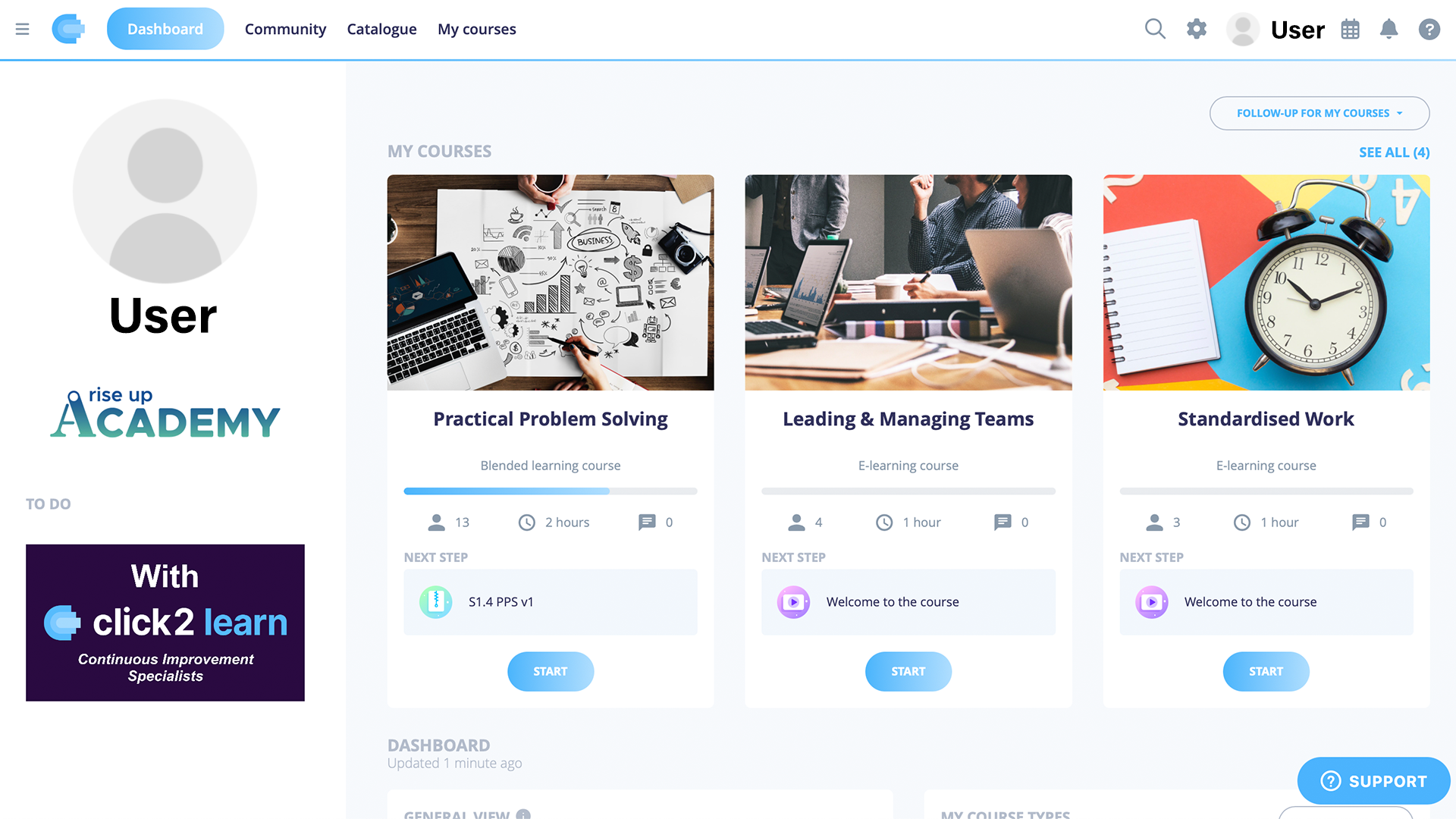

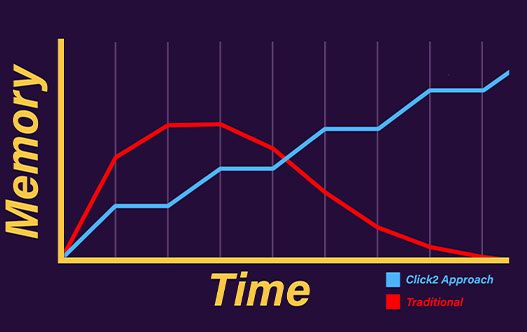

He added: “While we are also aware of the many issues businesses can have, we also recognise that sometimes time is short for many as they try and battle the day-to-day realities of work. Which is why we developed the click2 learn programmes which can be accessed at any time and on any device, and the training is flexible but effective.”

For more details about the courses and how they can help your industry, visit www.click-2.com